If you’re shipping liquid bulk products, you are likely familiar with bulk liquid tankers, along with totes and drums that may routinely transport your products. What you may be less familiar with are ISO tanks – another transport option for liquid bulk shippers that is becoming increasingly popular. In this article, we’ll introduce you to these tanks and tell you how ISO tank trucking companies can help you get your products in motion.

Introduction to ISO tanks

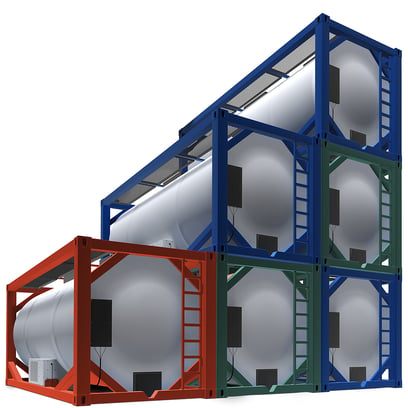

ISO tanks are steel cylinders that sit within a metal, wall-less box frame. They are given the name “ISO” tanks because they were designed in accordance with ISO standards from the International Organization for Standardization. ISO tanks are generally used to house bulk liquids, both hazmat and non-hazmat, for transportation and storage.

Design & construction

ISO tanks consist of a steel outer shell and typically include a liner (e.g., chemical liner, rubber lined, plating) that can be replaced during cleaning. Different liners are used for different products. For example, an ISO tank used for hazardous corrosives will likely have a different liner than a tank used for food products. The tank’s fittings and valves can also be customized to manufacturer/shipper specifications.

Storage capacity

Most ISO tanks are approximately 20’ long and 8’ tall and can hold roughly the same amount of liquid as a standard liquid bulk tank. There are also 40’ versions of the ISO tank that have a long, thin appearance.

Products stored

Nearly any liquid bulk product can be shipped in an ISO tank. Common products include chemical products, both hazmat and non-hazmat. These tanks have become a go-to option for products like corrosives that eventually wear down a tank’s structural integrity. It’s much cheaper to replace an ISO tank than an entire bulk tanker. Food-grade products and even Kosher food-grade products are also shipped in ISO tanks.

Tank storage

ISO tanks are typically stored at an “ISO depot,” which is basically an outdoor warehouse with ISO tanks stacked high and wide. However, manufacturers and shippers may also store tanks on site.

Tank washing

ISO tanks can be washed out at a common tank wash facility. However, most tanks are cleaned and stored at ISO depots, where their liners can be replaced if necessary.

ISO tank trucking companies

ISO tanks are typically transported by drayage providers and carriers that receive chassis from ‘power-only’ companies. ISO tank trucking is also managed by 3PL freight brokerages that specialize in bulk freight.

Loading and unloading

The ISO tank will be loaded at the top or bottom using a pump or air compressor. The tank is typically filled at a plant, dropped onto a chassis (if plant has its own crane), and then shipped to an ISO depot by a transportation provider for storage or directly to the recipient facility. For plants that do not have a crane onsite, heavy-duty jacks can be used to move empty tanks onto the chassis before being filled.

For unloading, the carrier will typically use a pump or air compressor to unload the product from the tank’s discharge valve. Some chassis are built so that the tank can tilt downward during the unloading process. After unloading, the empty tank will be returned to the ISO depot or the originating plant.

Benefits of ISO Tank Transport

- Cost Efficiency. Transportation with ISO tank trucking companies is typically less expensive than with regular bulk liquid tankers. ISO tanks maximize payload, are designed to be reusable, and can be transported via ship, rail, or truck without unloading and reloading the cargo. This seamless intermodal transport process can lead to substantial savings in both time and money.

- Safety and Security. ISO tanks are manufactured to adhere to strict safety standards. ISO tanks offer great stability for volatile products as there are few break points in the tank and less movement during transport – minimizing the risk of leaks and spills – compared to other liquid bulk modes. Additionally, the tanks are equipped with sophisticated locking mechanisms to prevent tampering and contamination, enhancing the security of the transported goods.

- Environmental Sustainability. The reusability of ISO tanks makes them an environmentally friendly choice. They reduce the need for disposable packaging materials and help lower the overall carbon footprint of shipping activities. Their design also minimizes residue left after unloading, reducing waste and facilitating easier cleaning and recycling.

- Flexibility and Accessibility. Another key strength of ISO tank transport is flexibility. ISO tanks can transition seamlessly between ship, rail, and truck, reducing handling and potential delays. Tanks can also be used for both one-way and round-trip voyages, and they can carry a variety of liquid products. They are also equipped with heating and cooling systems, making them suitable for transporting temperature-sensitive goods.

- Reduced Contamination Risk. Both ISO tanks and traditional liquid bulk tankers can be dedicated to a single product to eliminate cross-contamination risks. However, ISO tanks make this process easier and more practical, especially for companies that lease or purchase containers for exclusive use. The sealed, containerized nature of ISO tanks—combined with global standardization—simplifies product dedication and ensures consistent cleanliness across modes and borders.

Disadvantages of ISO Tank Transport

While ISO tank transport offers numerous advantages, it also comes with certain limitations.

1. Limitations on Over-the-Road (OTR) MovesOTR transport of ISO tanks is often restricted to shorter runs due to logistical and economic constraints. Most ISO tanks are dedicated to transporting a single type of product, which means that carriers are typically unable to reuse them during the return trip after unloading. Consequently, carriers are typically reluctant to engage in long-haul transport of ISO tanks unless economically justified by higher freight charges or other compensatory factors.

2. Specialized Equipment Requirements for Loading and UnloadingThe operation of loading and unloading ISO tanks requires specialized equipment, which is not universally available across all carriers. Facilities responsible for the loading and unloading need to be equipped with appropriate hoses, fittings, pumps, and a source of pressurized air or nitrogen gas. The lack of such equipment can lead to delays, increased handling costs, and restricted choice of carriers, impacting the overall efficiency of bulk liquid transport.

3. Regulatory and Compliance ChallengesTransporting liquids, particularly hazardous ones, in ISO tanks is subject to stringent regulatory requirements that vary by region and the nature of the cargo. Compliance with these regulations requires thorough documentation, proper labeling, and adherence to safety protocols, adding layers of complexity and the potential for regulatory hurdles. Failure to comply can result in fines and shipment delays.

Why Work with a Bulk Freight 3PL for ISO Tank and Bulk Freight Shipping?

When it comes to moving bulk freight—whether in an ISO tank, liquid bulk tanker, or dry bulk trailer—the logistics are complex, the regulations are strict, and the margin for error is small. That’s where a specialized bulk freight broker like Bulk Connection adds measurable value.

Access to a Vetted, Specialized Carrier Network

Bulk Connection maintains a vast network of pre-qualified carriers across North America, including those with ISO tank capabilities. Whether your shipment requires a standard tank truck or a container that will cross oceans and borders, Bulk Connection can match your load with the right equipment and expertise—fast.

Product and Mode Flexibility

One of the biggest challenges in bulk shipping is finding capacity for your specific product and mode. From hazardous chemicals to food-grade materials, and from ISO tank containers to pneumatic trailers, Bulk Connection understands the nuances of each transport method and can pivot quickly based on availability, geography, or urgency.

ISO 9001:2015 Certified Processes

Bulk Connection’s ISO 9001:2015 certification isn’t just a badge—it’s a commitment to documented, measurable quality in every shipment. This level of operational discipline means:

- Your freight is matched with vetted carriers who meet strict safety and service standards.

- There are consistent processes for vetting, communication, load management, and issue resolution that ensure accountability, safety, and on-time performance for every shipment.

Bulk Connection is a liquid bulk freight specialist with one of the largest networks of bulk carriers – including ISO tank trucking companies – in North America. If you’d like to learn more about entrusting your bulk freight transportation needs with a true expert, contact Bulk Connection today.